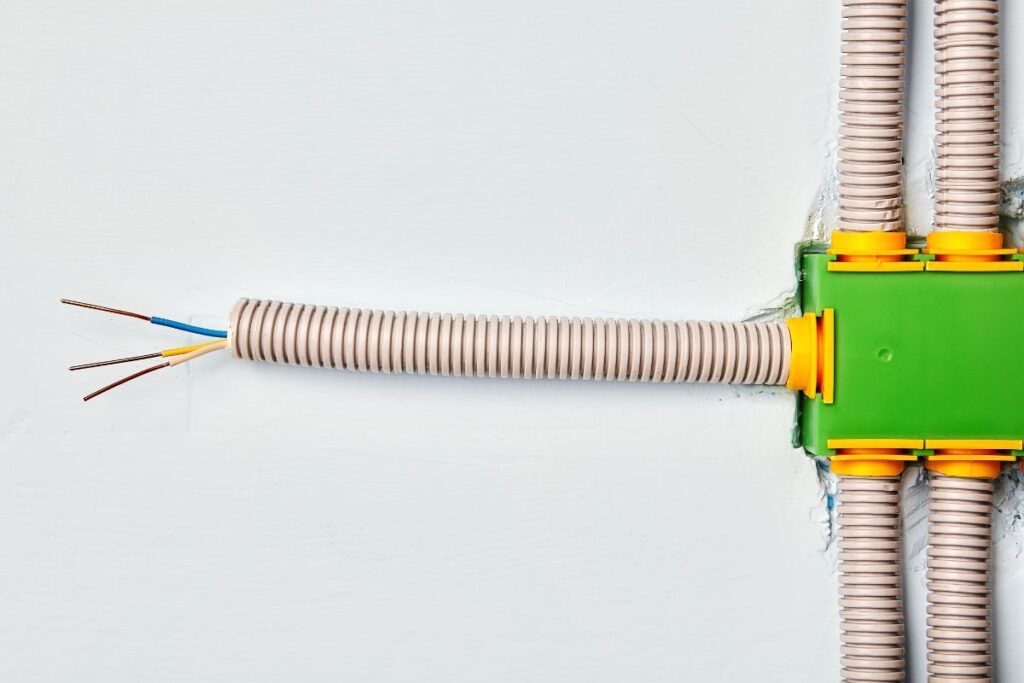

Conduits protect the cables from physical damage that produce electricity in our houses. Since different amp services require different wire numbers and sizes, the conduit size will vary.

Common electrical services include 100, 200, 300, and 400 amps. You need 1¼ inch conduit for 100 amps, 2 inches for 200 amps, 2.5 inches for 300 amps, and 3 inches for 400 amps. The size may differ based on the wire size and the number of wires to put inside the conduit.

Multiple factors can affect the conduit size for these electrical services. This article will elaborate on the conduit sizes for 100, 200, 300, and 400 amp services, the factors to consider, and the NEC conduit size requirements.

Check out our list of top-handpicked products for all your electrical, appliance, and HVAC system needs to keep your home running smoothly.

This post includes some affiliate links.Determining conduit size based on the ampacity

Determining the conduit size based on the ampacity of your electrical service takes work.

The simplest way is to refer to the National Electric Code (NEC), which has tables about the right conduit size for different electrical services and the wire types and sizes.

Determining the right conduit size is very important.

It allows you to decide the number of wires or cables to pull without damaging the insulation and exposing the wires.

Knowing the right conduit size will also help to avoid using an oversized or undersized conduit, preventing wire damage and increased cost.

To determine the conduit size, you need to know certain things:

- The number of conductors needed by the electrical service.

- The conductor size and material

- The conduit type you are using

- The cross-sectional area of the wires used (chapter 9 from NEC)

These will help you select the correct size for your electrical service.

NEC (National Electric Code) conduit size requirements

To understand the conduit size requirements by NEC, you need to have the NEC book and open chapter 9.

According to the National Electric Code, you need to consider three factors to meet their conduit size requirements:

- The number of cables to put in the conduit

- The cross-section area of the cables

- The number of bends in the conduit

Let’s take an example.

You have four 8-gauge wires with THHN insulation and two 4-gauge wires with THW insulation.

The 8-gauge wires will have a cross-section of 23.61 square mm or 0.03659 square inches.

The 4-gauge wires will have a cross-section of 62.77 square mm or 0.09729 square inches.

So, the total cross-sectional area of the wires will be:

(23.61 sq. mm) x 4 + (62.77 sq.mm) x 2 = 219.98 square mm.

Now, the NEC says that the conduit will provide 53% space for one wire, 31% space for 2 wires, and 40% space for 3 or more wires.

Based on this, you can determine the conduit size using the cross-sectional value you received earlier.

If you use all 6 wires, you need 40% space in the conduit. So, divide the value by 0.4.

219.98 / 0.4 = 549.95 sq. mm.

Based on this value, you need to find the conduit type by consulting the book.

For example, if you use electric conduit tubing, the closest size is a 1-inch conduit, giving you at least 39% fill for three wires.

Factors affecting the conduit size selection

A few factors will affect the conduit size selection :

- The number of wires and area occupied by them

- Number of bents

The number of wires and area occupied.

The US National Electric Code follows the following specifications while choosing the conduit size:

- For 1 wire, the conduit should provide 53% space.

- For 2 wires, the conduit should give 31% space.

- For 3 or more wires, the conduit should give 40% space.

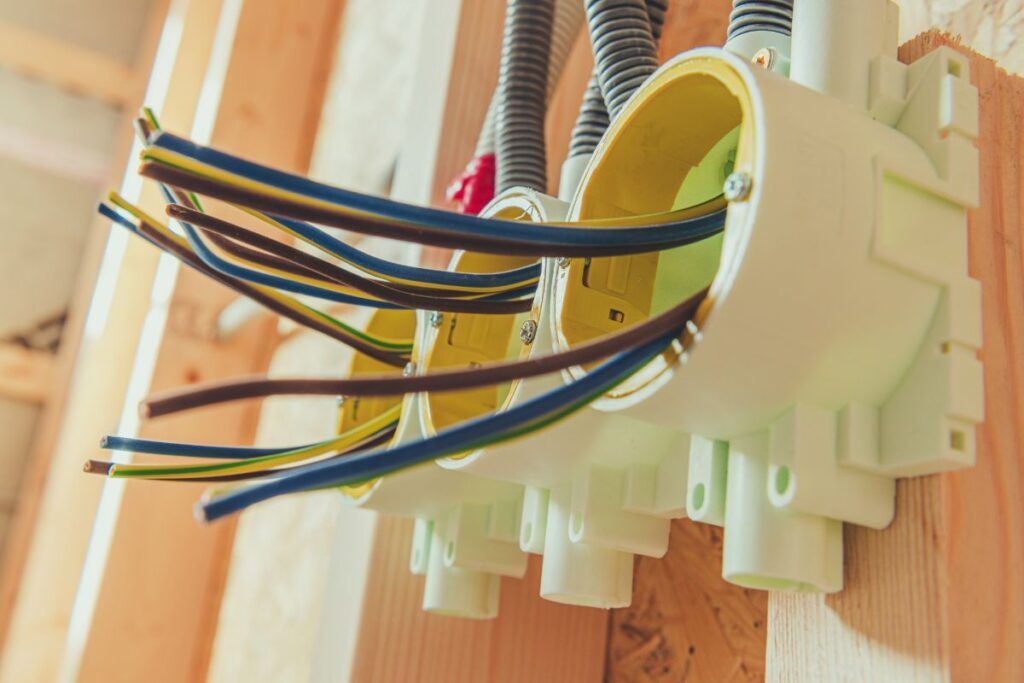

For example, let’s assume you have a 200 amp service.

The entrance cable will have 3-wire conductors for a single phase or 4-wire conductors for a 3-phase service.

The cable should receive at least 40% of the total conduit space.

Wire thickness

Thick wires will need bigger conduits than thinner wires.

If you use multiple thick wires, you need a slightly bigger conduit than the recommended ones.

For example, if you have a 200 service and want to use copper wires, you need four 2 AWG copper wires.

The recommended conduit size for a 200 amp service is 1.5 to 2 inches.

You should upgrade the size to 2.5 inches for thicker wires.

That is how the conduit size gets affected.

Number of bents

The number of 90-degree angle bending will also affect the conduit size.

If you need more than two bends at a 90-degree angle, your conduit size will reduce from the average size.

More than 2 bends will reduce the maximum space by 15%.

Choosing conduit material for high ampacity service

Different conduit materials are used for the electrical services, and the material is chosen based on performance and reliability.

Here are some best conduit material types you can use for high ampacity services.

EMT or Electrical Metallic Tubing

Conduits made of metal are commonly used conduits.

Despite being metallic, it is thin, which makes it easier to bend.

However, the major disadvantage of metallic conduits is you can thread them. The material is ideal for concrete and indoor environments.

Intermediate Metal Conduit

The next material is intermediate metal or IMC, slightly thicker than the EMT.

So it can handle the physical force and save the wires from physical damage.

You can use IMC for high ampacity services for underground and outdoor purposes.

Rigid Metal Conduit

A rigid metal conduit, or RMC, is the next commonly used conduit for electrical services.

It is made of galvanized steel and contains different sizes.

The material is strong, and you can connect threaded fitting to the conduit material.

So, it can be ideal for high-ampacity services.

PVC conduits

PVC, or polyvinyl chloride, is considered ideal for most high-ampacity services.

It is lightweight, corrosion-resistant, and flexible.

As a result, you can use it for outdoor purposes.

But the downside of this conduit type is that it gets easily affected by the sun’s UV rays.

So, for safety, do not expose the conduits to direct sunlight.

There are two common types of PVC – Schedule 40 and Schedule 80.

Based on the wire size and material, you can choose one of them.

Reinforced Thermosetting Resin Conduit or RTRC

The next conduit material type is RTRC.

You can use it as an alternative to PVC conduits.

These conduit types have multiple features that make them better than PVC conduits.

The material is fiberglass. It is made with tension-winding strands of fiberglass over a rotating mandrel.

The strands are impregnated with resin and then cured under high temperatures.

The conduit is low-burn through, contains UV stability, and can maintain its shape.

It is where it beats the PVC conduits.

Common Conduit sizes for 100, 200, 300, and 400 amp service

100 amp services are commonly used in smaller houses with a few electrical appliances.

Most people upgrade their service to 200 and 300-amp services due to the increased usage of electrical appliances.

400 amps are quite a huge service.

Houses with multiple electrical appliances and a detached location will require a 400 amp service.

Since these services are common, house owners would want to know the conduit sizes for wiring them.

The conduit size will differ based on the ampacity service:

Conduit size for 100 amps

If your house is smaller with 2-3 electrical appliances and you do not plan to add any extra appliances, 100 amp service would be enough.

Use a 3-wire cable from the meter base to the main disconnect box or panel.

For this service, you need 4 AWG copper or 2 AWG aluminum or copper-clad wires.

The minimum conduit size you need will be 1.25 inches to protect these wires.

You can go for PVC Schedule 40 or 80 gray electric conduits.

You can also use the slightly larger conduit to maintain the 40% space rule. Use a 1.5 or 2-inch conduit to pull the wires easily.

Conduit size for 200 amps

Most people upgrade from 100 to 200 amps.

It is good for houses that need more than a few electrical appliances for a smooth and speedy life.

The wire size for 200 amps is 2 AWG copper or 4 AWG aluminum or copper-clad aluminum.

Suppose you use aluminum triplex cable for single-phase.

In that case, you need one 4 AWG wire for neutral connection, two 4 AWG wires for hot connections, and one 4 AWG ground wire.

So, you have 4 wires here. To maintain the 40% space rule, the minimum conduit size for 200 amps has to be around 1.5 to 2 inches.

Experts recommend RMC for overhead services.

For underground services, there are 4 best options besides RMC:

- IMC

- RTRC-XW

- EMT

- Rigid Schedule 80 or 40 PVC

You can increase the size to 2.5 inches for easier pulling and enough space for the wires.

Conduit size for 300 amps

300 amps are also good for houses with only important electrical appliances.

Besides, you may also add 2-3 more appliances in the future.

If you have a 300 amp service, you need 250 kcmil copper wire or 350 kcmil aluminum or copper-clad aluminum wires.

For underground, you need 300 to 500 kcmil wire, based on the wire material.

If you are running 3 or 4 conductors, a 2 to 2.5-inch conduit will work fine for 300 amps.

You can upgrade it to 3 inches to keep the wires safe.

Since the wires will be thicker, a slightly bigger conduit will save the wires from getting exposed.

You can use a PVC schedule 40 or 80.

Conduit size for 400 amps

400 amp service is huge and is needed for houses with multiple heavy-duty appliances.

Besides the appliances, it is installed for houses with a detached location, for instance, a swimming pool with a mini-fridge, outhouse, workshop, garage, or studio.

Since the service is quite high, you will need a 400 kcmil copper wire or a 600 kcmil aluminum or copper-clad aluminum wire.

Since the wire sizes will be thick, you need a slightly bigger conduit than the other amp services.

A PVC Schedule 40 conduit of 3 inches would be enough for 400 amp service.

If you run more than 3 wires, increase the conduit size by 0.5 inches, i.e., 3.5 inches.

Oversized and undersized conduit considerations

Electrical services with different ampacity will need different conduit sizes.

It would be best to use the minimum conduit sizes for proper wiring.

Some homeowners use oversized conduits so that the wires can go through the conduit, and you can pull them out easily.

There is no problem using an oversized conduit.

But, since the conduits can be costly, an oversized conduit will hurt your pocket but keep the wires fine and in good shape.

If you want to increase the conduit size, increase it only by 0.5 inches.

If you need a 2-inch conduit, you can use a 2.5-inch conduit for safety.

On the contrary, you should not use an undersized conduit.

You will struggle to pass the wires through the conduit.

Besides, the wires will struggle for adequate space inside, the insulation may chop off, and the wires can get exposed.

Exposed wires coming in contact with the wrong materials will lead to short circuits and fire hazards.

So, do not ever choose any undersized conduit to save money.

Types of conduit for commercial and residential service

Commercial and residential services sometimes use different types of conduits for their usage methods.

However, they may also use the same type of conduit.

It depends on the quality of the conduit and how they are used.

Commercial services

For commercial services, a single phase is limited to 200 amps.

Larger installations need 3-phase.

To use conduit for commercial applications, here are some options:

- Intermediate metal conduit:

- Rigid metal conduit

- Flexible metal conduit

- Liquidtight flexible metal conduit

- Rigid PVC conduit

- Electrical metal tubing

Residential services

The minimum service and meter socket for residential uses is 200 amps for underground and 100 amps for overhead services.

When it comes to using a conduit for residential services, you can use the following options for the conduit type:

- Rigid metal conduit

- Electrical metal tubing

- Electrical non-metal tubing

- Intermediate metal conduit

Impact of conduit fill on ampacity rating

The conduit size differs based on the ampacity rating because the wire sizes differ.

Thicker wires will need bigger conduits to stay fit inside them.

According to the NEC, the conduit fill specifications include the following:

- 1 wire: Maximum fill will be 53% of the space inside the conduit.

- 2 wires: Maximum filling will be 31% of the space inside the conduit

- 3 or more wires: Maximum filling will be 40% of the space inside the conduit

You should maintain these specifications for all conduits and ampacity ratings.

The electrical service will only work well if you maintain the conduit fill rules by NEC.

Also read: Can You Run Romex In Conduit?

Final thoughts

Choosing the right conduit size is very important as it helps to keep the wires safe from physical damage. Smaller wires can hurt the wires, damage their insulation, and expose them. So, choose the right size.

You can go for slightly bigger conduits for multiple or thick wires. You should follow the NEC rule about the conduit fill to keep the wires in good shape.

100, 200, 300, and 400 amps are the most used services, and that’s why their conduit sizes are mentioned in this article. If not a bigger or right size, choose at least the minimum conduit size recommended for these services.

What size and type of conduit do I need for 320 amps?

320 amps is a new residential service used in place of 400 amps. Since there is not much difference, use the same conduit size recommended for 400 amps, i.e., 3 inches PVC schedule 40.

What size of conduit do I need for 12 AWG wire?

The conduit size is based on the conduit fill. The size of 12 AWG wires will depend on the number of wires and the electrical service you use.

Reference: Electrical Conduit.